The Operating System for Modern Metal Fabrication

Stop bleeding margin on administrative chaos. BMARK connects engineering data with shop-floor reality—accelerating BOM creation via AI, tracking real-time costs, and eliminating production bottlenecks.

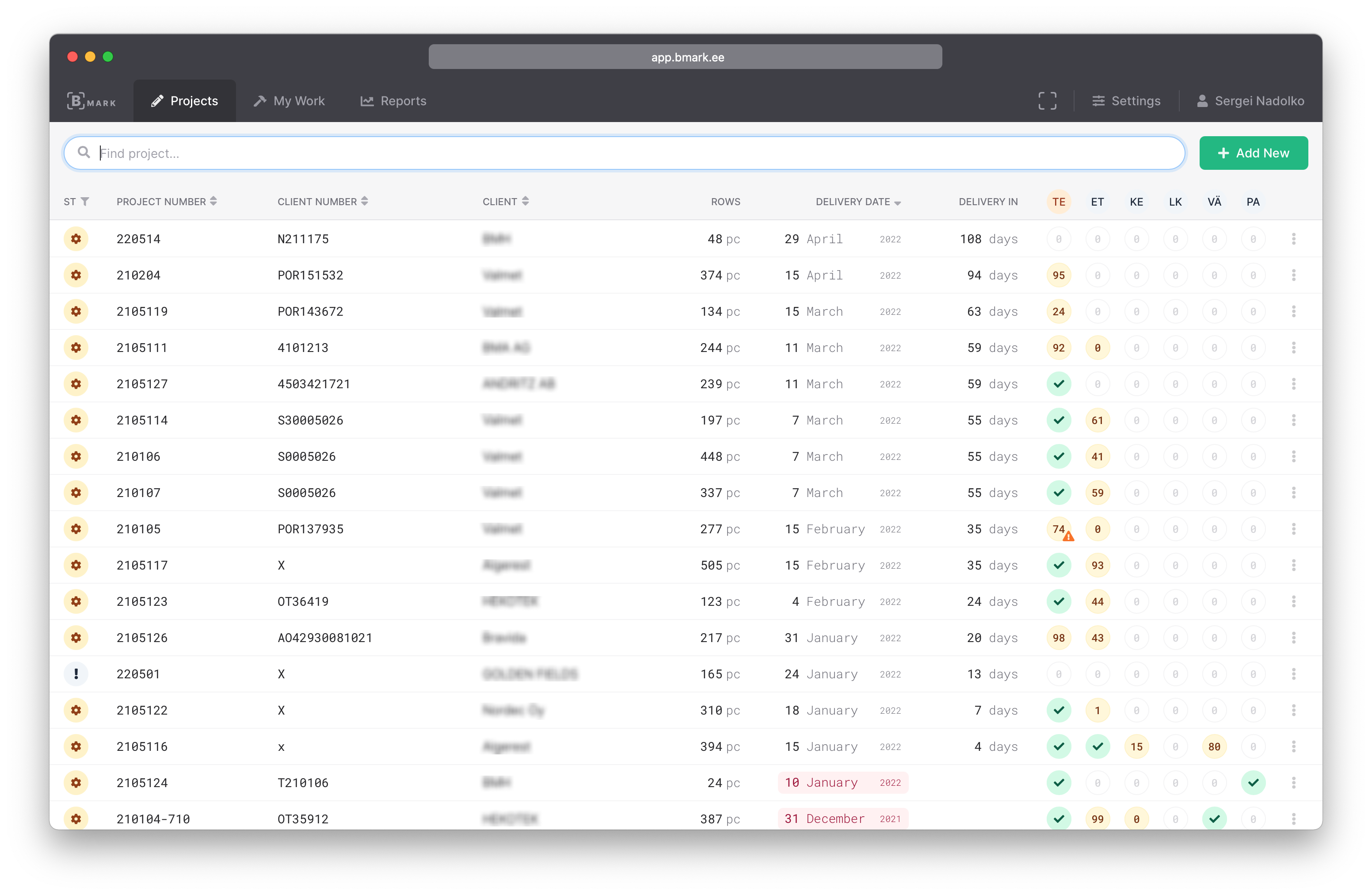

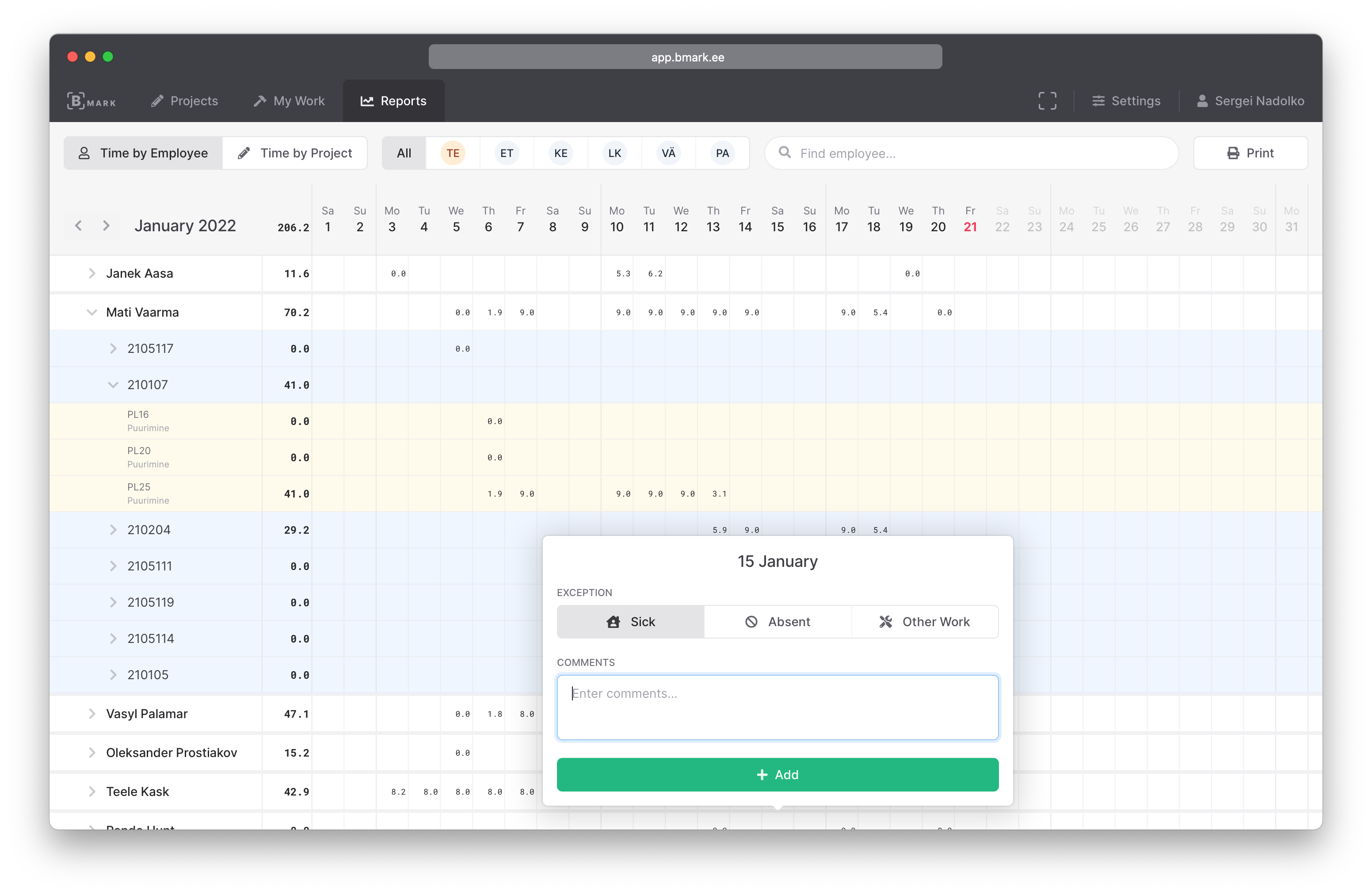

Real-Time Production Intelligence

Eliminate the 'black box' of the shop floor. Gain immediate visibility into project status, identify critical path bottlenecks instantly, and receive predictive alerts for deadline slippage before it impacts client relationships.

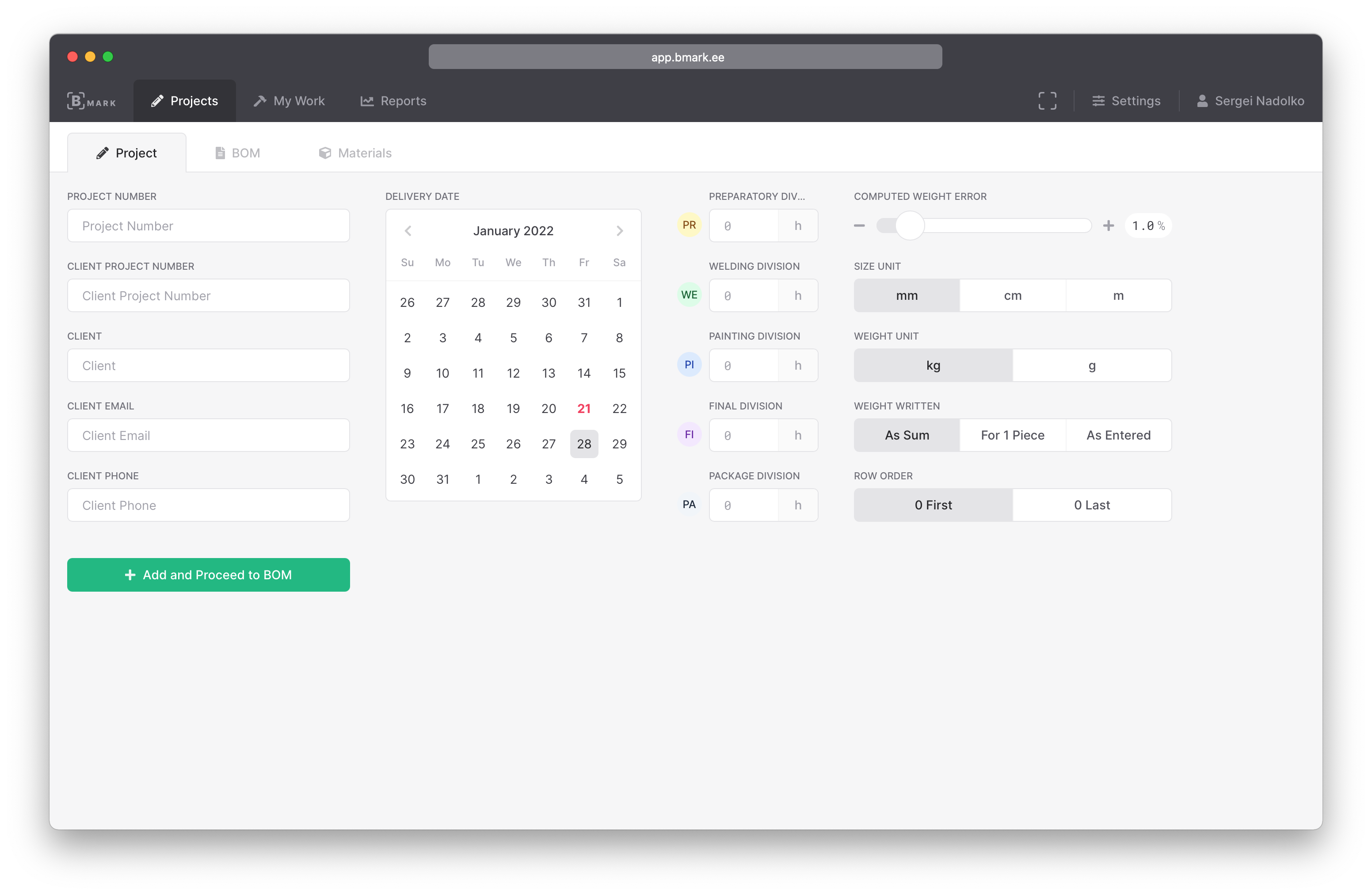

Precision Engineering Integration

Bridge the gap between design and fabrication. Define granular budgets, enforce strict delivery timelines, and utilize automatic weight anomaly detection to ensure the physical product matches the digital twin.

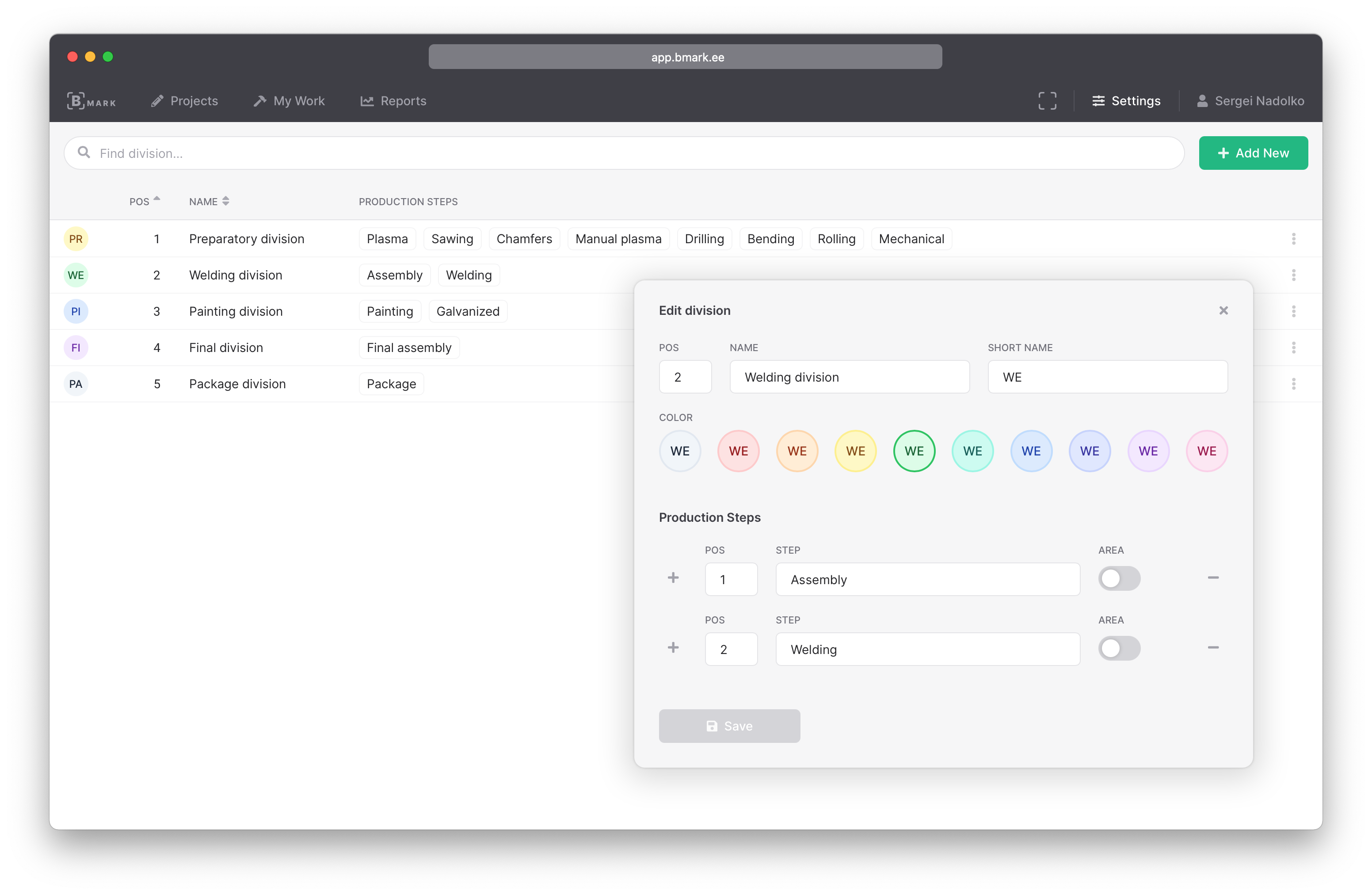

Dynamic Workflow Configuration

Don't change your process to fit software. Configure divisions and production milestones to mirror your unique operational language. Visual color-coding provides executive-level status assessment at a glance.

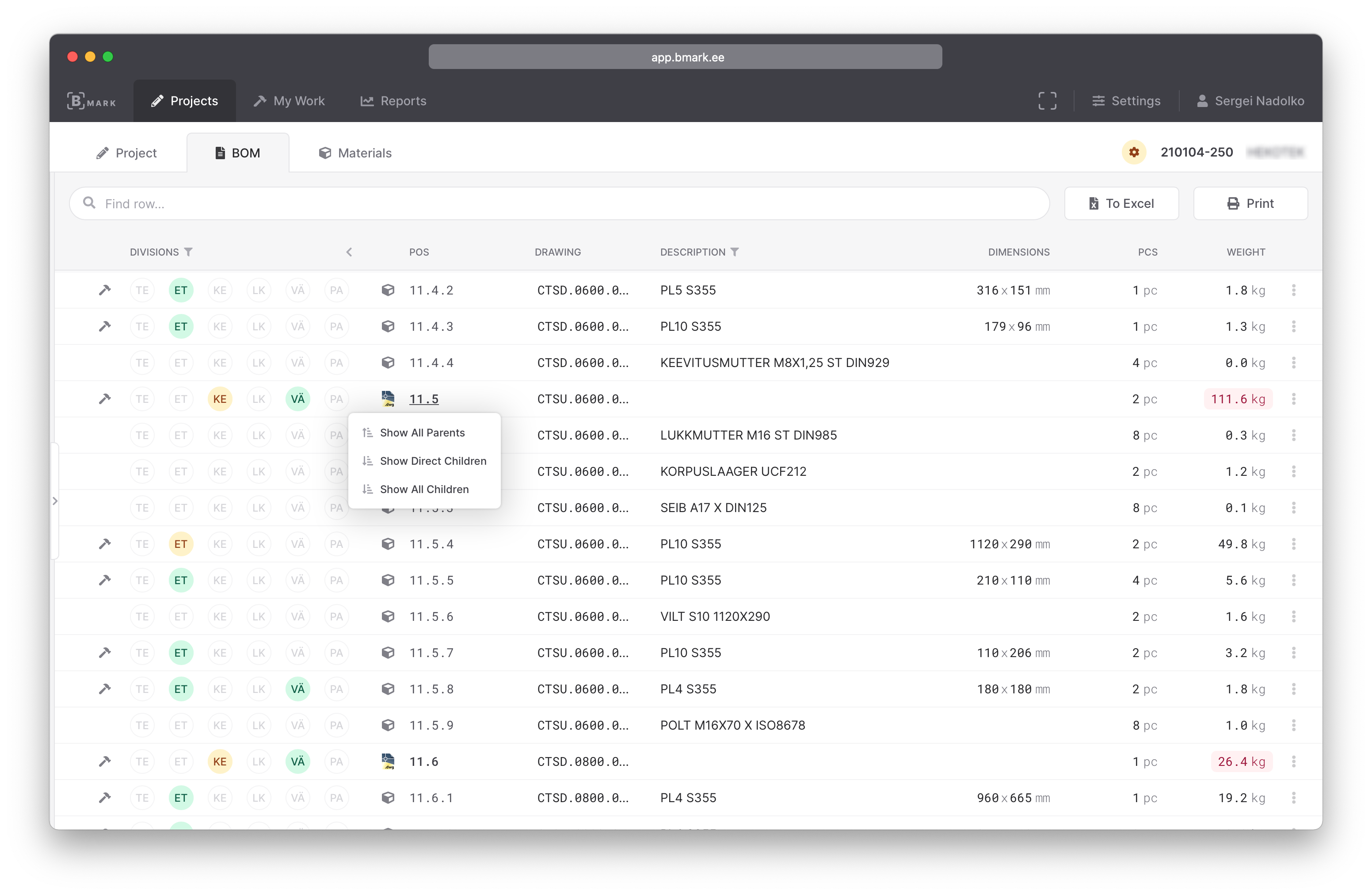

AI-Accelerated Data Entry

Let AI do the heavy lifting. BMARK parses your PDF drawing packs to build the initial production tree, drastically reducing typing time. You retain full control to validate, edit, or manually input edge cases, ensuring 100% data integrity before hitting the floor.

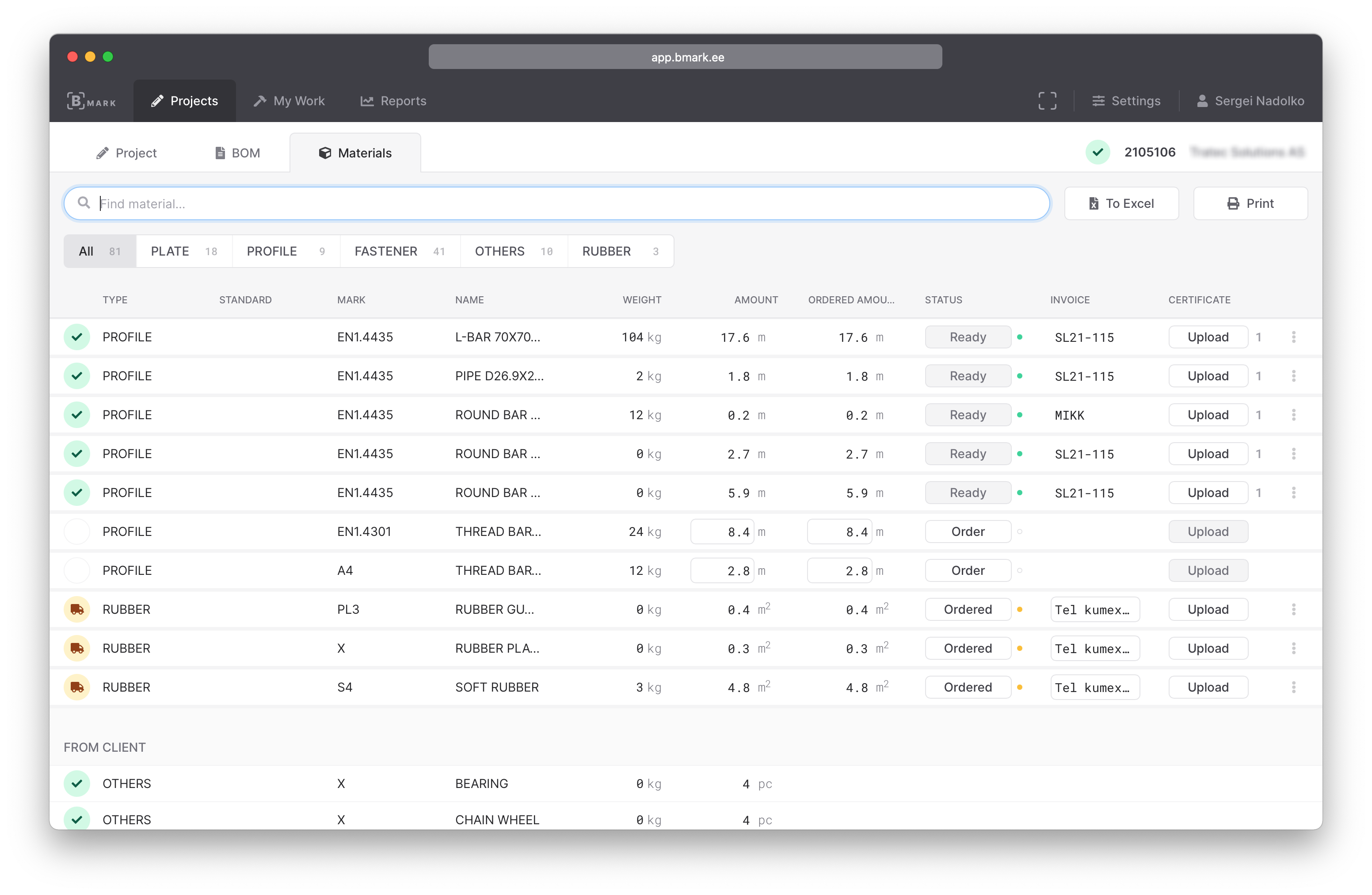

Smart Procurement & Costing

Automate the aggregation of materials by type and grade. Streamline the supply chain by tracking deliveries against production schedules and mapping invoice data directly to assembly lines for precise job costing.

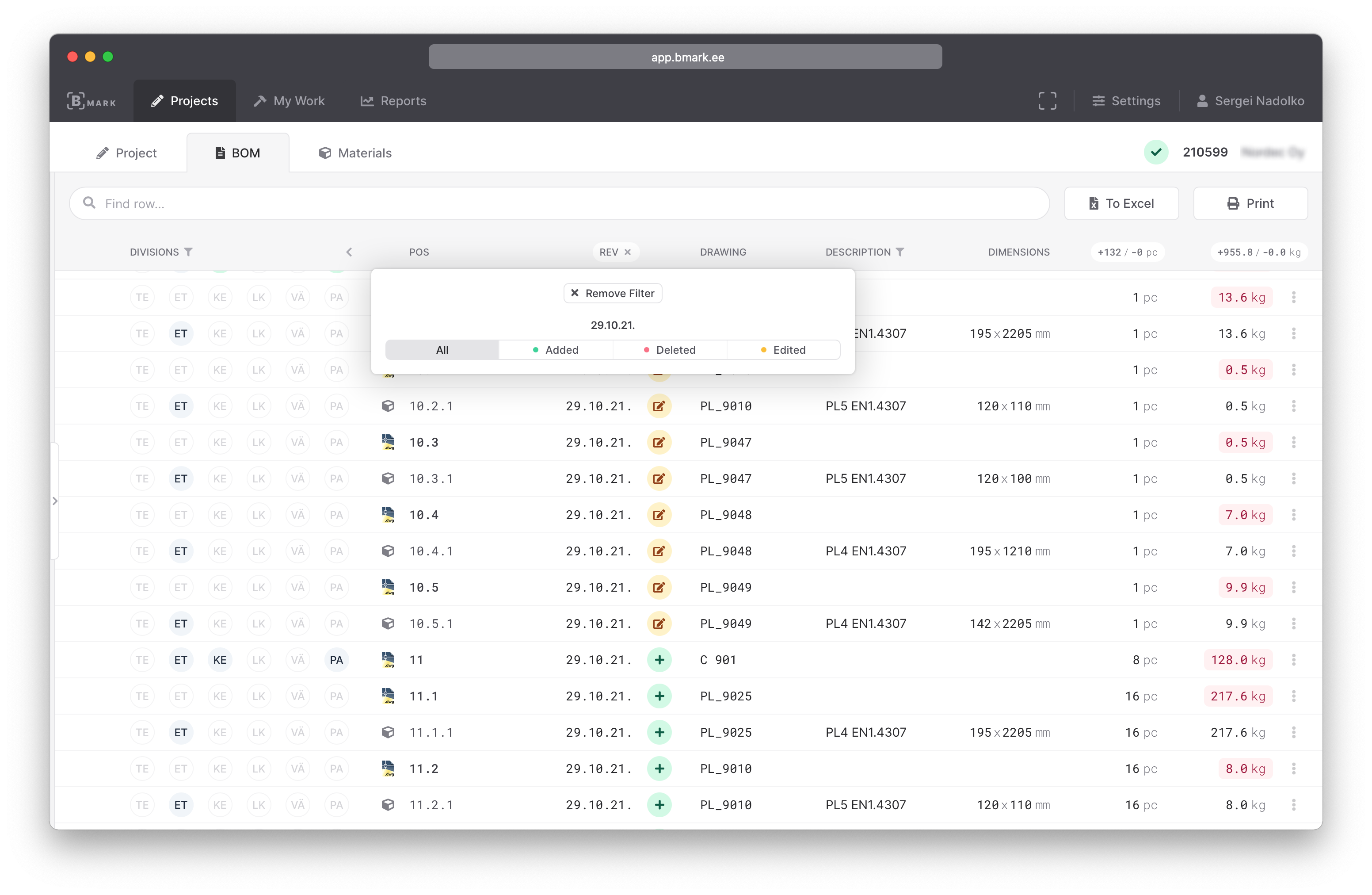

Revision Control System

Revisions kill margins. BMARK turns chaos into control. Instantly halt production on specific drawings, broadcast changes to the floor, and release version-controlled updates with full audit trails.

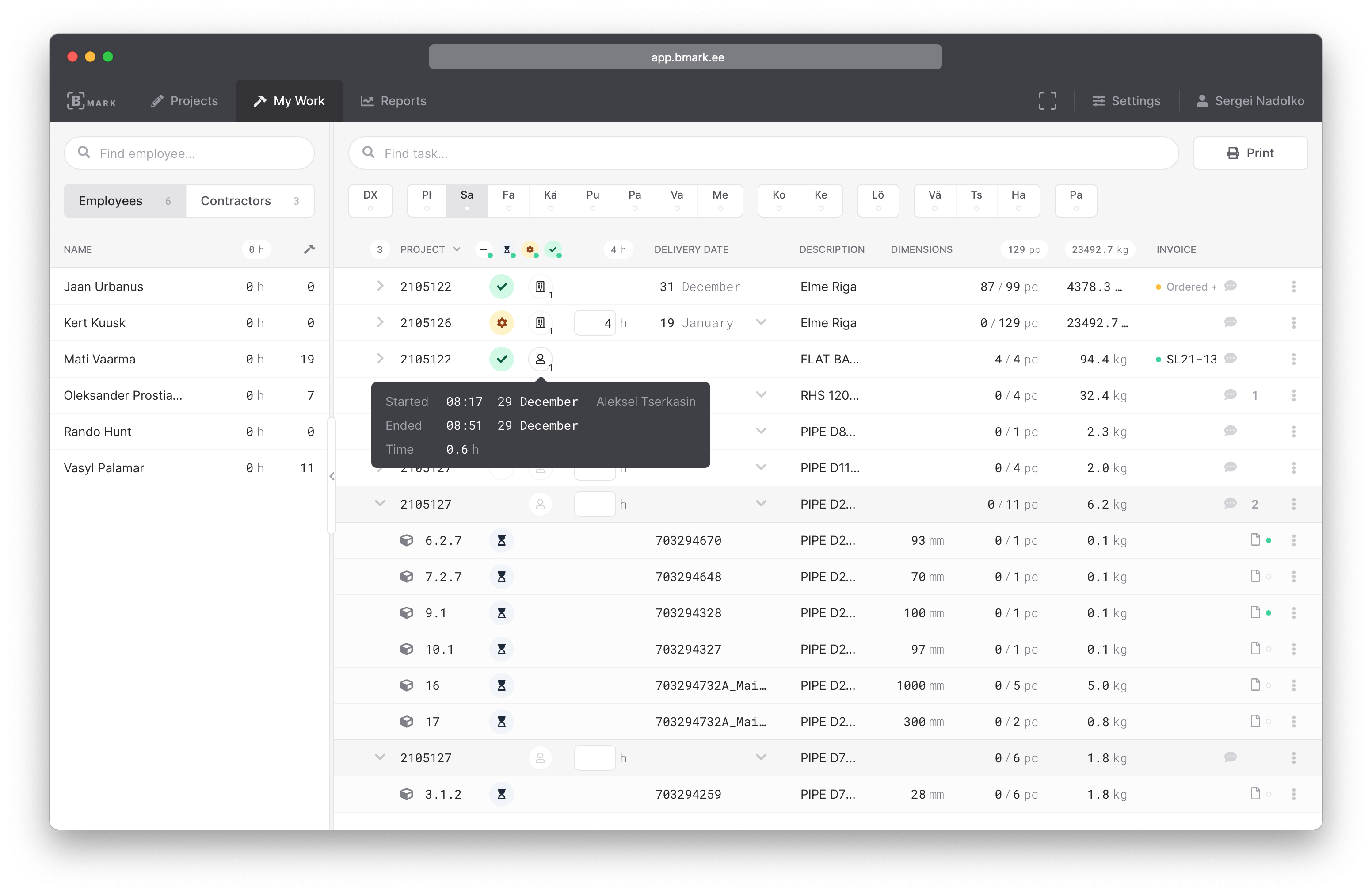

Workforce & Contractor Management

Orchestrate your labor force. Assign internal teams or external contractors to specific work packages. Monitor output quality and quantity in real-time to ensure labor costs remain within the estimated budget.

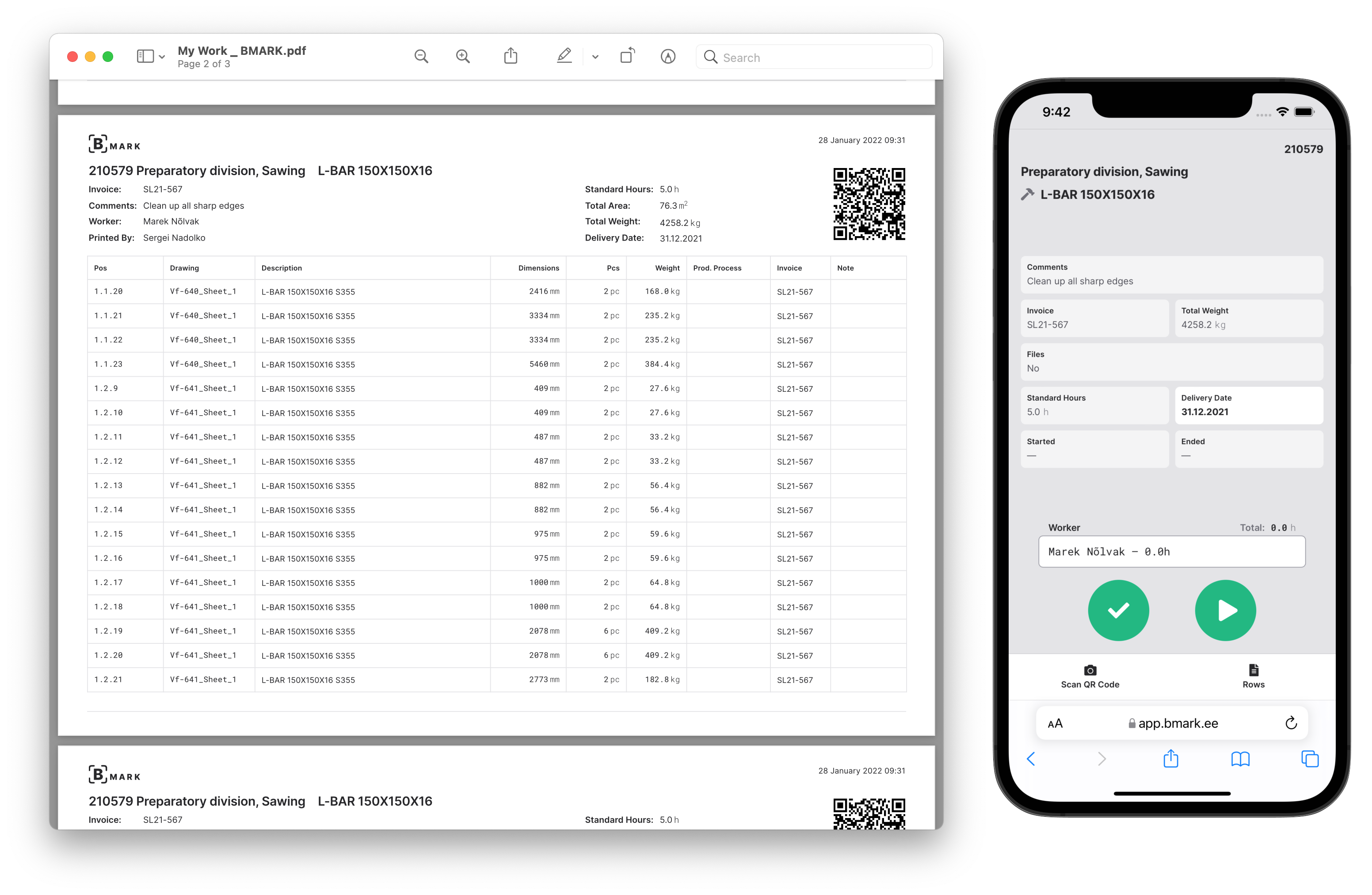

Digital Shop Floor (QR)

Digitize the floor without complex hardware. Workers interact via QR codes on physical job sheets, bridging the analog-digital divide. This provides instant feedback loops on task completion and labor hours.

Granular Profitability Analysis

Stop guessing which projects make money. Capture exact labor hours and material usage via mobile inputs. Visualize actual vs. estimated costs in real-time to protect margins and bid smarter on future projects.

Korduma Kippuvad Küsimused

How does BMARK get data from our drawings?

BMARK utilizes a hybrid workflow. Our AI parses standard PDF engineering drawings to extract bulk data automatically. Your engineers then review, validate, and manually adjust any specific details, ensuring speed without sacrificing accuracy.

Is BMARK suitable for custom project-based manufacturing?

Yes. Unlike rigid standard ERPs, BMARK is specifically engineered for high-mix, low-volume project manufacturing common in steel and metal fabrication.

Does it require expensive hardware installation?

No. BMARK operates as a cloud-based solution. Shop floor reporting is handled via standard smartphones using secure QR code scanning.

Ready to optimize your production?

Join the metal fabrication companies already using BMARK to reduce waste and increase margins.

Book a Demo